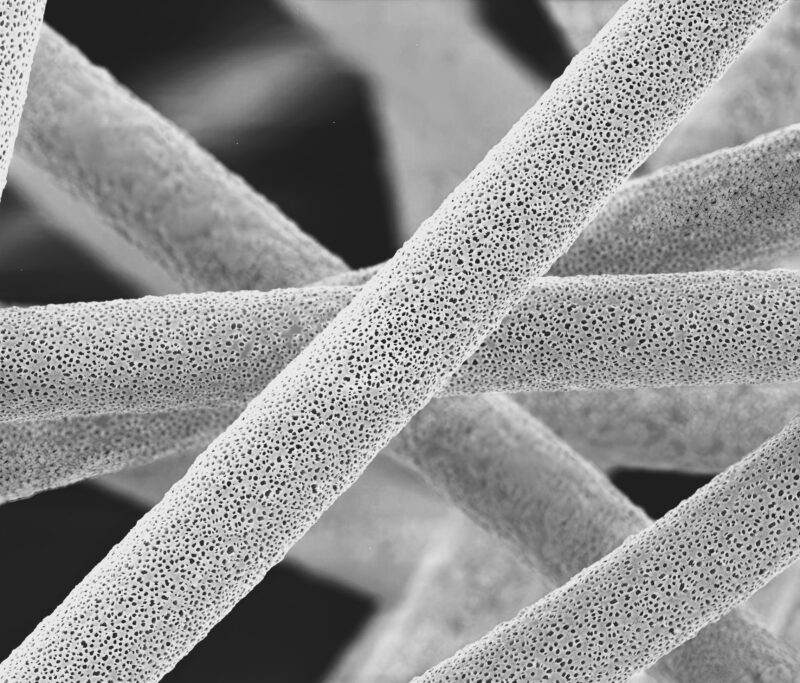

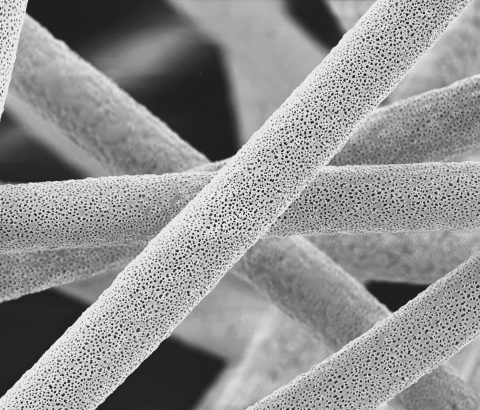

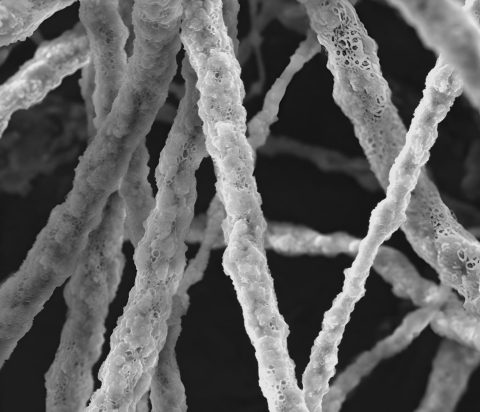

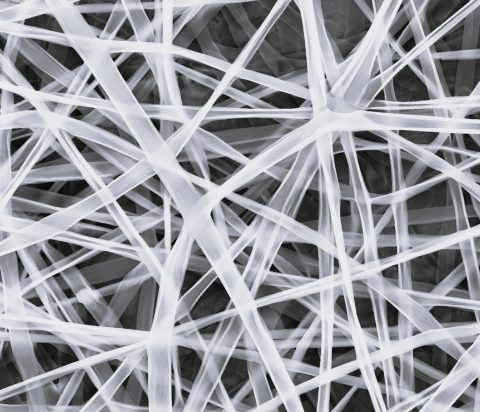

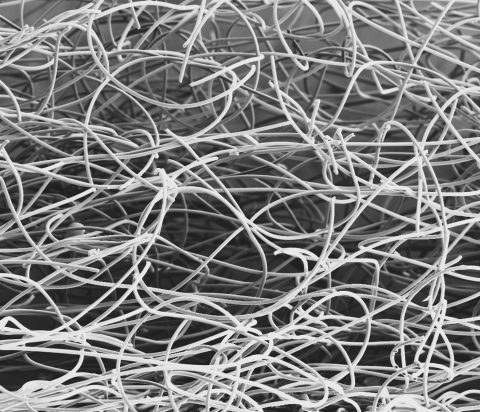

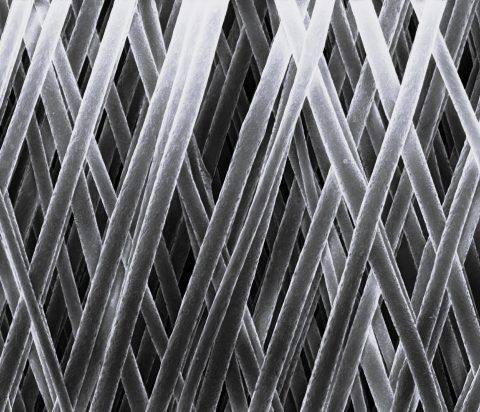

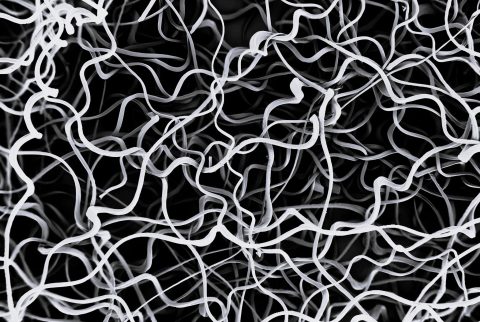

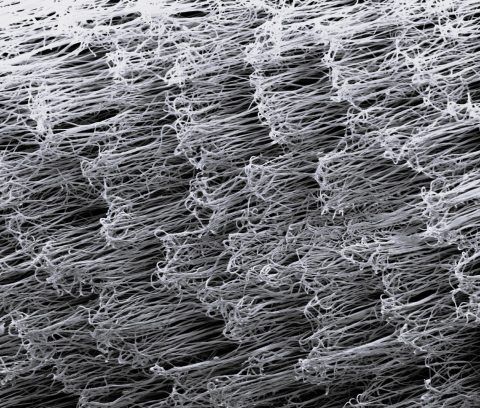

VIVOLTA’s proprietary medical electrospinning technology can create nano- and micro-fiber materials with unique properties that other manufacturing process cannot

Electrospun nano- and micro-fiber materials can serve as scaffolds in the body, helping to restore healthy tissue at the site of injury or disease and accelerate healing. Other manufacturing processes cannot match the small size scale and precise arrangement of electrospun fibers that is essential for mimicking the architecture of native human tissue and guiding optimal healing. Because of these unique characteristics, electrospun materials can add value to a wide variety of medical implants with the goal of improving clinical outcomes and patient care.