Materials Science

Robust supplier network of world-class biomaterials for electrospinning · Extensive selection of off- the-shelf polymers · Deep expertise for optimal polymer selection

VIVOLTA is the healthcare industry’s trusted electrospinning partner for contract development & manufacturing of electrospun medical devices.

We are a fully integrated contract development and manufacturing company specializing in electrospinning. We enable our partners to develop, scale, and manufacture breakthrough electrospun medical devices that greatly improve patients’ lives.

Guiding the body to heal itself.

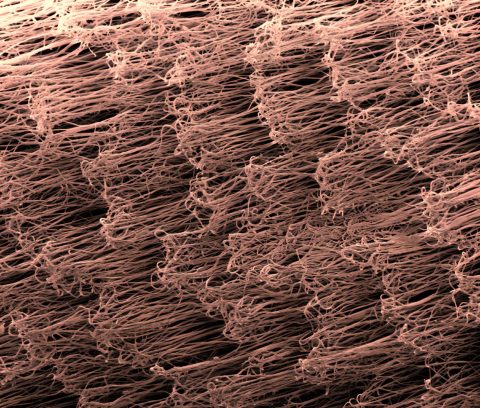

Medical electrospinning is a unique manufacturing process capable of producing nano- and microfiber-based materials using electrostatic forces. Electrospun biomaterials offer many performance and process advantages over traditional medical materials due to their biomimetic architecture resembling native human extracellular matrix. Whereas traditional medical materials are prone to scar tissue encapsulation and poor tissue integration, VIVOLTA’s electrospun biomaterials are readily recognized by the body, promoting healthy tissue restoration – effectively, guiding the body to heal itself.

VIVOLTA offers a full suite of electrospinning solutions spanning from concept development to commercial manufacturing. In development, we first consider the specific design requirements of our clients’ target medical applications, then we engineer electrospun materials with the ideal properties to meet those requirements and enhance product performance. VIVOLTA’s contract manufacturing services consolidate our clients’ supply chains into a one-stop-shop for electrospun medical products and components – managing raw material vendors and fully integrating post-processes such as laser cutting, packaging, and labelling.

Robust supplier network of world-class biomaterials for electrospinning · Extensive selection of off- the-shelf polymers · Deep expertise for optimal polymer selection

Broad know-how electrospinning many natural and synthetic polymers · Proven track record developing a wide range of medical products · Custom test method development for functional prototyping.

Fully integrated in-house engineering team · Specialists

in automation, sensors, and in-line QC systems · Custom-

tailored electrospinning equipment for every product.

Pioneer of the MediSpinTM automated electrospinning production platform · Vertical integration of custom equipment engineering · ISO Class 7 clean-rooms in our ISO13485 certified facility.

At VIVOLTA, we can produce a wide variety of electrospun material forms ranging from flat meshes, tubes, and even complex 3D shapes using both natural and synthetic, resorbable and biostable polymers. Based on our broad portfolio of carefully selected medical materials, our bio- materials can be engineered to safely resorb over a period of time commensurate with tissue healing and restoration, or safely remain in the patient for a lifetime.

VIVOLTA’s innovative electrospun biomaterials instruct a more restorative response by the body, improving product performance and reducing complications. Our electrospun biomaterials add value to a wide range of medical applications including cardiovascular, orthopaedic sports medicine, general surgery and soft tissue reconstruction, advanced wound healing, and drug delivery.

The MediSpinTM is the world’s first and only fully automated, scalable medical electrospinning production platform capable of the quality, consistency, and throughput required by the medical industry. This transforms electrospun product concepts into commercial reality.

In the MediSpinTM, all critical manufacturing parameters are rigorously controlled using sensors and feedback systems, without operator intervention, guiding the entire electrospinning process in real time. Every product is verified using fully-automated, in-line quality systems and data-capturing. Based on these advantages, there is no other system in the world capable of the MediSpin’s combined quality and throughput.

Electrospun medical materials offer numerous biological benefits, making them highly valuable for various biomedical applications. Some of the key biological benefits of electrospun medical materials include:

Biomimetic Architecture: Electrospun nano- and microfibers closely mimic the fibrous structure of the natural extracellular matrix (ECM) found in human tissues. This biomimetic architecture promotes cell adhesion, proliferation, and differentiation, facilitating tissue regeneration and repair processes.

Enhanced Cell & Tissue Response: The high surface area and porosity of electrospun materials allow for increased cell-material interactions, particularly cell adhesion, proliferation, and differentiation. Cells can attach, spread, and migrate more effectively on the scaffold, leading to improved cell viability and functional tissue formation. This is especially important for medical devices whose purpose is to restore damaged or diseased tissue.

Bioresorbable: Electrospun materials can be designed to be biodegradable, meaning they can be safely broken down and resorbed by the body over time. This property is crucial in the design of tissue scaffolds, because as the electrospun material gradually degrades it allows newly formed tissue to replace the implant and its function.

Anti-microbial: Bioresorbable electrospun materials can also be designed to incorporate antimicrobial agents, so that as the implant is safely resorbed, it also releases antimicrobial agents preventing acute or chronic infection. In this strategy, the localized, targeted use of antimicrobial agents, can greatly reduce the need for systemic administration of antibiotics, thereby counteracting side effects and antibiotic resistance.

Tissue Integration: Electrospun materials integrate seamlessly with the surrounding tissues, reducing the extent of chronic inflammation and adverse foreign body reactions. This integration fosters better tissue regeneration and long-term stability of the electrospun implant without deleterious scar tissue formation.

Controlled Drug Delivery: Electrospun fibers can be engineered to encapsulate drugs or growth factors, offering controlled and sustained release directly at the injury site. This feature enables targeted drug delivery, which is beneficial for localized treatments – particularly by improving their potency and reducing side effects.

Angiogenesis: Due to their high porosity and tunable pore size, electrospun materials promote angiogenesis, the formation of new blood vessels. Proper angiogenesis is essential for providing oxygen and nutrients to developing tissues, accelerating the healing process.

Modulation of Cell Behavior: Electrospun materials can be functionalized by incorporating bioactive molecules, such as peptides or growth factors. These functionalized materials can modulate cell behavior, guiding cellular activities like stem cell differentiation and tissue-specific functions.

Enabling Advanced Therapies: Electrospun materials provide an excellent platform for advanced stem cell-based therapies and tissue engineering. They can act as carriers and scaffolds for stem cells and provide the necessary cues for guiding stem cell differentiation into specific cell and tissue types. Eventually, electrospun scaffolds incorporating growth factors and stem cells may be able to replace damaged or diseased organs.

Mechanical Properties: Electrospun scaffolds can be engineered to possess mechanical

properties that match those of the target tissue. For example, bone scaffolds can be designed to have high mechanical strength, while cardiac scaffolds can have elasticity similar to heart tissue. Similar to specialized human tissues, electrospun materials can be engineered to be anisotropic – e.g. stiff in one direction and elastic in the other – offering a large design space for new medical implant design and development.

Non-immunogenic: VIVOLTA’s electrospun medical materials are non-immunogenic, meaning they do not trigger an immune response. This is due to their composition based on biocompatible synthetic and natural polymers that have a proven clinical track record of safety. This characteristic is crucial for implantable materials, as it reduces the likelihood of rejection by the body’s immune system.

These biological benefits highlight the tremendous potential of electrospun medical materials in regenerative medicine, tissue engineering, drug delivery, and various other biomedical applications.

Medical electrospinning offers several advantages that make it a valuable manufacturing technique in the field of medical implants, regenerative medicine, tissue engineering, and drug delivery. Some of the key advantages include:

Tunable Fiber Structure: Medical electrospinning produces fibers with diameters in the nanometer and micron range, mimicking the natural extracellular matrix of tissues. Using this process, fiber diameter is highly tunable based on the target design requirements. Electrospun materials possess high surface-to-volume ratio, enhancing cell adhesion, proliferation, and differentiation, as ideal scaffolds for tissue regeneration.

Tunable Porosity: In concert with fiber diameter, mesh porosity can be finely tuned using medical electrospinning to achieve the desired functional attributes of the material. Highly porous electrospun materials facilitate nutrient and oxygen transport, enabling better cell viability and tissue growth. High porosity also aids in the effective loading and release of drugs, growth factors, or bioactive molecules. Conversely, densely constructed electrospun meshes can be used to block cell infiltration, serving as barriers for different medical applications.

Customizable Mechanical Properties: The electrospinning process allows for precise control over the material composition, structure, and resulting mechanical properties of the scaffolds, ranging from highly elastomeric to relatively stiff. Different polymers, blends, additives, and post-process steps can be used to tailor the electrospun material’s mechanical properties for specific applications.

Biocompatibility: Electrospun fibers can be fabricated from both synthetic and natural materials with excellent clinical track records of biocompatibility and safety. As such, electrospun materials can reduce the risk of adverse reactions or toxicity.

Permanent or Resorbable: Medical electrospinning can be applied to a wide range of natural and synthetic polymers, both resorbable and non-resorbable, allowing for huge design space in creating the ideal fiber-based material for different medical applications

Controlled Drug Delivery: Electrospun fibers can encapsulate drugs or bioactive agents and offer controlled and sustained release. By carefully tuning the drug loading, fiber size, and porosity, the drug elution profile can be precisely controlled according to the needs of the therapy. VIVOLTA is also able to coaxially electrospin drug-loaded fibers to achieve elution characteristics that would otherwise be technically impossible.

Readily Integrated: Electrospun materials can be readily applied to other medical device components, like metallic stent frames and textiles, without sutures, greatly reducing the cost of manufacturing and unlocking new functionality. Vivolta’s manufactured electrospun components can be reliably integrated into our client’s supply chains thanks to our ISO13485 certification.

Scalability: At VIVOLTA, medical electrospinning processes can be scaled up for commercial production on our MediSpinTM platform, making large-scale manufacturing of electrospun medical products possible.

Cost-effective: Compared to R&D electrospinning processes, VIVOLTA’s MediSpinTM system allows for large-volume, cost-effective manufacturing of electrospun medical products based on its fully automated design and integrated quality control systems.

Innovative Research: Medical electrospinning continues to pave the way for innovative research in tissue engineering and regenerative medicine, enabling the development of advanced therapies and solutions for currently incurable medical conditions.

These advantages make medical electrospinning a valuable manufacturing technology with significant potential to revolutionize the medical and healthcare industries.

Medical electrospinning is a unique process technology used to manufacture innovative medical products, particularly medical implants. It involves the electrostatic spinning of biocompatible polymers – both natural and synthetic into nanofibers or microfibers. These fibers possess a high surface-to-volume ratio and mimic the extracellular matrix of tissues, making them attractive biomaterials for various biomedical applications.

Fiber-based biomaterials produced by medical electrospinning act as scaffolds when implanted in the body. They support cell growth, proliferation, and differentiation. These scaffolds act as a three-dimensional framework for tissue regeneration and repair, instructing the body to heal itself. As such, electrospun biomaterials bring distinct advantages to a wide array of medical applications such as cardiovascular, general surgery and soft tissue reconstruction, advanced wound healing, orthopaedic sports medicine, drug delivery systems, and tissue engineering

"*" indicates required fields