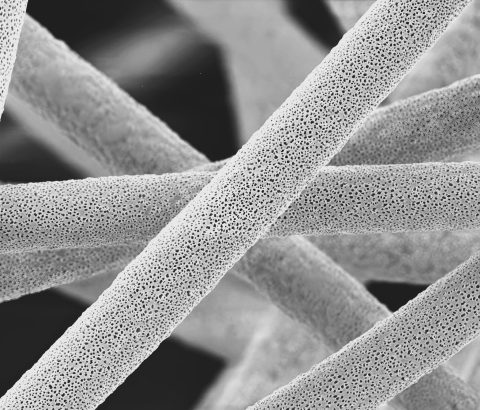

VIVOLTA’s electrospinning development services incorporate iterative design thinking approach and quality-by-design principles, accelerating our clients' breakthrough electrospun medical products.

VIVOLTA builds quality into every step of the product design process by ensuring only medical implant grade polymers are selected for electrospinning development even at the earliest stages of feasibility testing. During development, we adhere to Design Control principles in accordance with our ISO13485 certification as a medical device component manufacturer. Importantly, our development team always incorporates design-for-manufacturing stress testing from the earliest phases of development to ensure all manufacturing processes are scalable and robust. At the (pre-)clinical manufacturing phase, our validated manufacturing processes are continuously monitored by integrated, automated quality systems embedded in the MediSpinTM production system – guaranteeing traceability of every part produced back to the specific polymer batch used to make it.