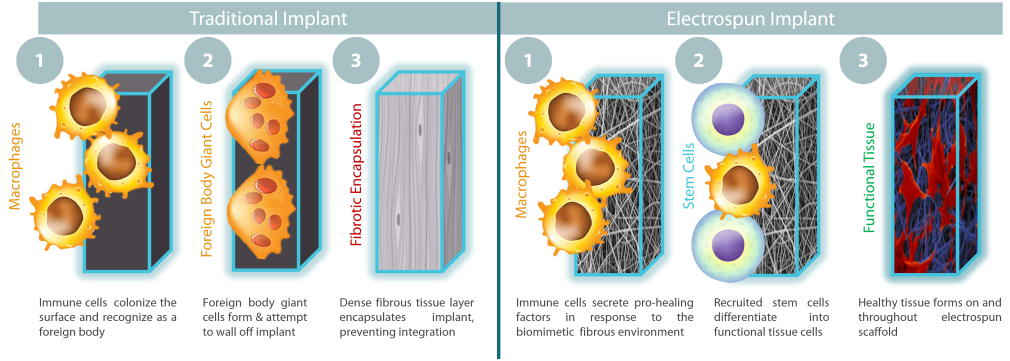

Guiding the body to heal itself

Electrospun biomaterials integrate with the body and accelerate healing.

Electrospun biomaterials are particularly useful in implantable medical products because their fibrous architecture mimics the native extracellular matrix of human tissue. When this architecture is carefully engineered, electrospun biomaterials promote new tissue ingrowth and revitalization of damaged tissue, thereby accelerating healing. Moreover, electrospun biomaterials typically avoid an adverse fibrotic response and resulting scar tissue formation inside the patient endemic to traditional materials.